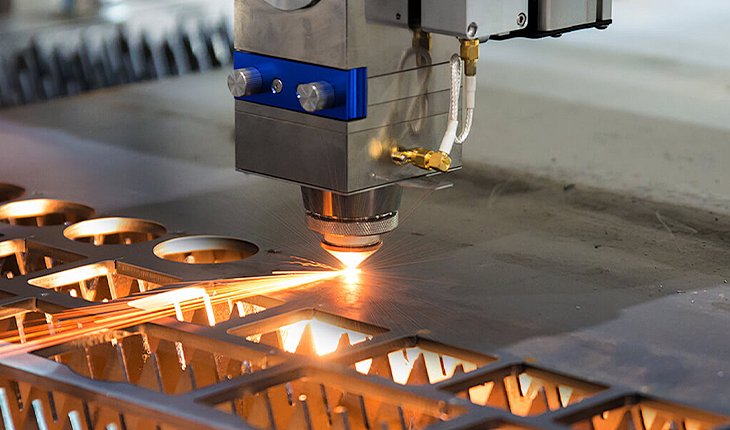

Fiber laser cutting machines can ensure product quality, reduce processing time for different materials of metal, and thus reduce unnecessary time for manufacturers and customers. Moreover, using fiber laser cutting to process workpieces does not result in any contact with the workpiece surface. This is a non-contact processing method. For products with high surface requirements, the application of laser cutting technology in the flat mouth and bottom process of cups and pots has significant advantages

(1) Fast cutting speed and high efficiency: Compared with traditional cutting methods, flat bottomed laser cutting machines have faster processing speed and higher efficiency;

(2) High cutting accuracy: The laser cutting machine precisely completes the cutting and processing of the pot mouth and cup bottom by controlling the intensity and position of the laser beam, and the incision is smooth and free of burrs, without the need for secondary polishing;

(3) Energy saving and environmentally friendly without consumables: Compared with traditional cutting methods, laser cutting technology adopts non-contact cutting, which has no consumables loss