Many customers prefer to pursue the cutting speed of metal laser cutting machines when learning about them

Although cutting speed has a significant impact on the quality of stainless steel plate cutting, it is not necessarily the faster the better. The optimal cutting speed is

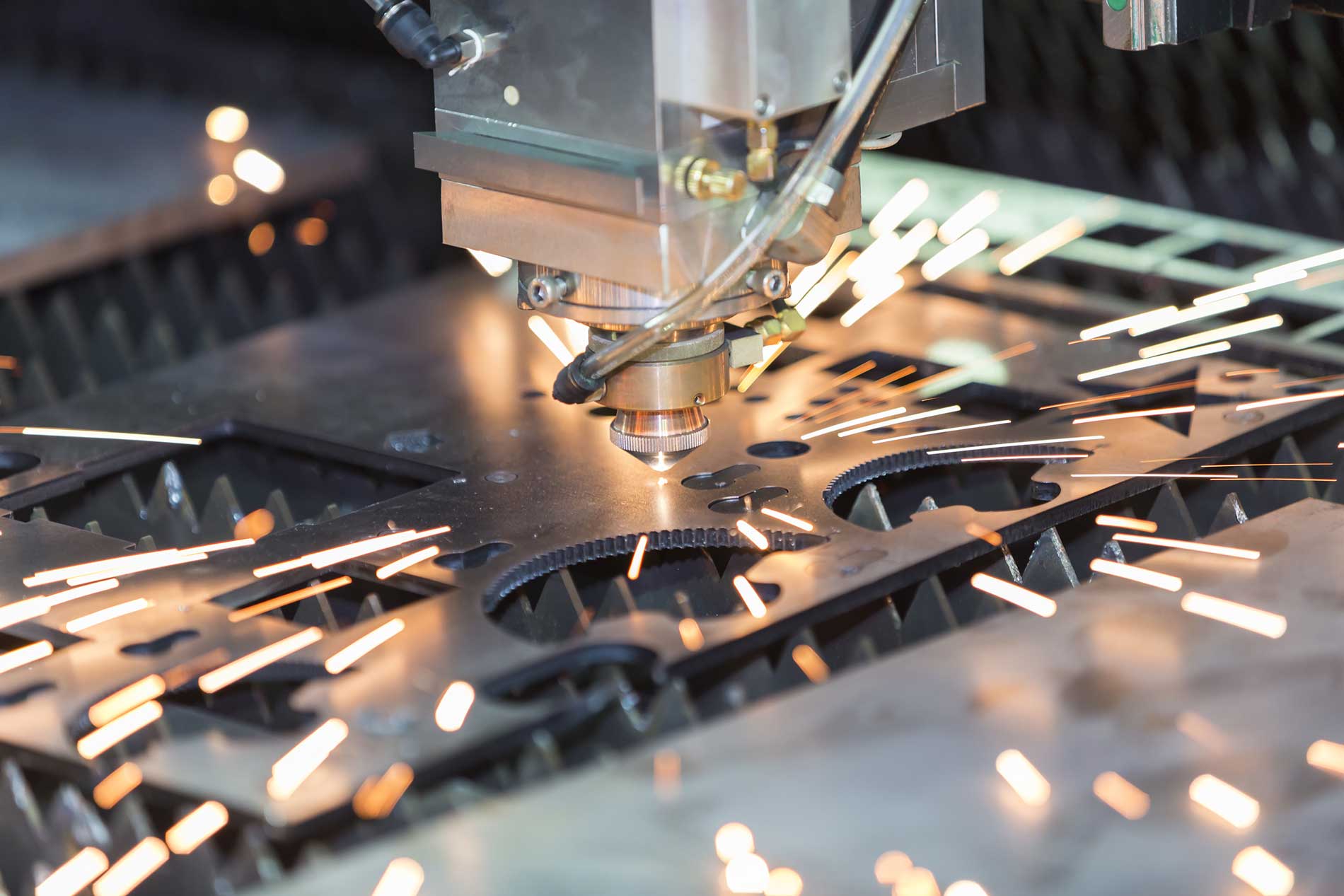

The cutting speed makes the cutting surface a relatively smooth line, with no slag produced at the bottom.

If the cutting speed of the laser cutting machine is too fast, it will cause the steel plate to be unable to be cut through, resulting in sparks splashing, slag formation in the lower half, and even burning of the lens. This is because the cutting speed is too high, the energy obtained per unit area is reduced, and the metal is not completely melted; If the cutting speed is too slow, it is easy to cause the material to melt too much, the cutting seam to widen, the heat affected zone to increase, and even cause the workpiece to overheat. This is because the cutting speed is too low, and energy accumulates at the cutting seam, causing the cutting seam to widen and the molten metal to not be discharged in a timely manner, forming slag on the lower surface of the steel plate, resulting in cutting defects.

So, how should we adjust when such a problem arises?

The input heat of the workpiece is determined by both the cutting speed and the laser output power. Therefore, the relationship between the change in input heat and processing quality caused by the increase or decrease in cutting speed is the same as that of the change in output power. In general, when adjusting processing conditions, if the purpose is to change the input heat, the output power and cutting speed of the laser cutting machine will not be changed at the same time. Only one of them needs to be fixed and the other needs to be changed to adjust the processing quality.