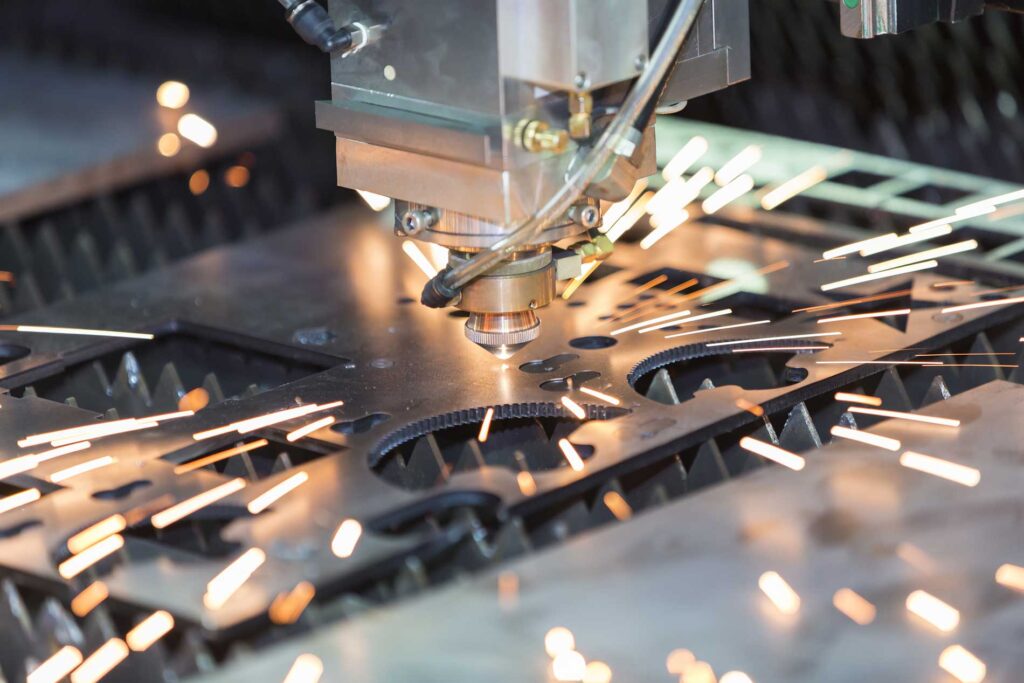

Metal laser cutting machines are highly sought after by manufacturers in the field of metal processing due to their fast cutting speed, high efficiency, and good cutting effect. However, some minor issues may arise during use, such as the problem of saw teeth during laser cutting processing.

The main reasons for saw teeth in laser cutting are as follows.

1、 Vibration.

If the laser cutting machine vibrates, the products it cuts will have serrations. It is divided into two reasons. One is the external situation of the machine, such as when the machine is cutting, such as the water tank or exhaust fan, it will not be too close. If it is too close to the machine, it will vibrate the machine when it is running. When the machine is cutting materials, it will produce vibration, which will affect the edge effect of the cutting.

2、 Machine parallelism.

If the parallelism of the machine is not installed properly, it will not be smooth during operation, and it will also shake during operation, resulting in jagged edges in the cut products.

3、 The lens is not locked tightly.

Sometimes, if the lens is not locked tightly, the lens will also vibrate when the machine is running, and the light will also vibrate when the machine is cutting, resulting in poor product quality and the occurrence of serrations.

4、 Gear seat and other aspects.

If the edge of the gear seat is close to the seat, causing slipping and other situations, it can also cause this situation to occur.

5、 The slider is worn.

There is wear inside the slider or there is a lot of stuff stuck in the beads of the slider, causing it to shake when running on the guide rail. So when cutting materials, there will be many serrations.

6、 The guide rails are not parallel.

The two guide rails in the Y direction are not installed parallel, which can cause them to get stuck during operation and have serrations during cutting. If the laser cutting machine has serrations during cutting, you can hold down the laser head with your hand to prevent it from shaking while running. If it doesn’t, it must be a problem with the slider; If it still exists, then you need to check the belt and gear. If there is a new machine, it must be installed improperly or its control drive and motor are not paired.