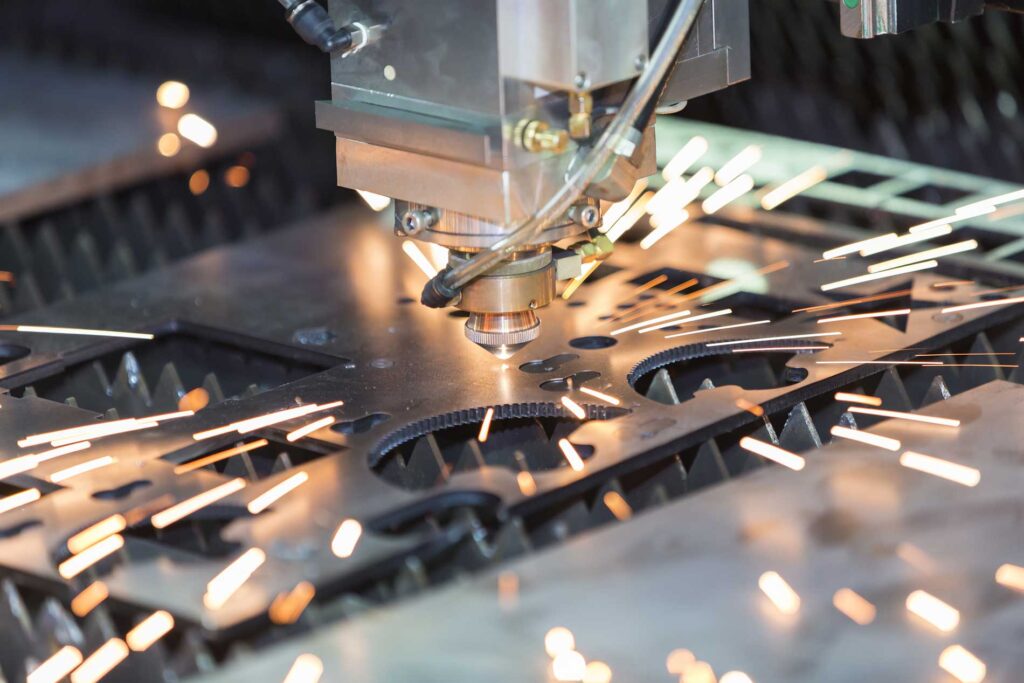

With the continuous advancement of technology and changes in the market, the development trend of laser cutting machines will become more automated and intelligent. Laser cutting technology is now widely used in the processing of various metal materials. Do you know the benefits of using a laser cutting machine to cut carbon steel plates? Today, Yiqiang editor will give you a lecture:

1. Efficiency: The carbon steel laser cutting machine uses a laser beam for cutting, which can achieve high-speed and high-precision cutting. Compared with traditional mechanical cutting, it is faster and more efficient.

2. Good cutting quality: The carbon steel laser cutting machine has a high laser power and a small heat affected zone, so it can achieve high-quality cutting effects, with a flat cut, no burrs, and a smooth cutting surface.

3. Wide range of materials that can be processed: Carbon steel laser cutting machines can not only cut metal materials such as carbon steel, stainless steel, aluminum alloy, copper, copper alloy, etc., but also non-metallic materials such as wood, acrylic, rubber, etc.

4. High degree of digitization: The carbon steel laser cutting machine controls the movement axis and laser beam position through a digital control system to ensure cutting accuracy, and can generate CAD drawings or process files to achieve automated operation, making the production process more efficient and fast.

Overall, laser cutting technology is an advanced processing method that has good cutting effects and wide application prospects for metal materials such as carbon steel plates.