Tube laser cutting machine adopts with FSCUT3000S system, which is designed for tube cutting control, support standard tube(retangle, circle, oval, ellipse and obround etc.) , free form , and steel channels(T/U/H/L shape) production of high precision and efficiency.

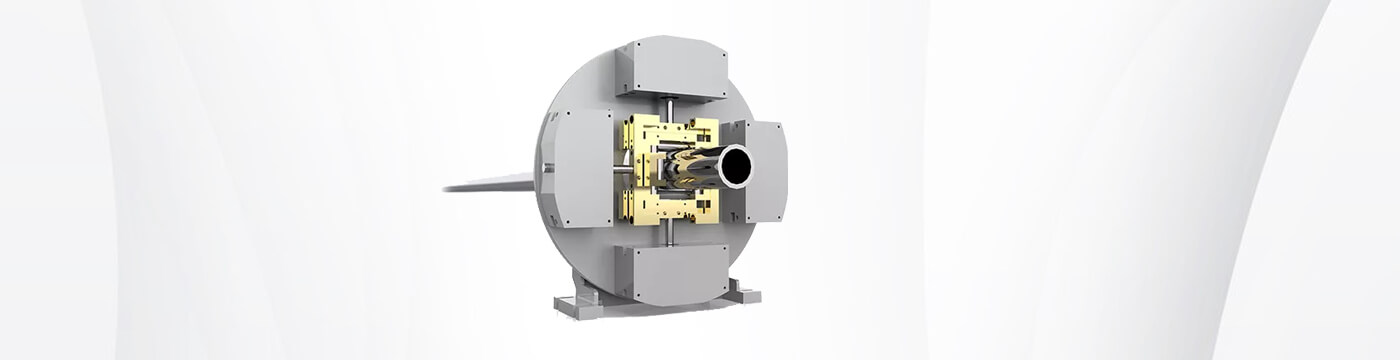

3. One-key self-centering, fast clamping, rapid cutting.

4. The clamping force of the chuck can be adjusted according to the wall thickness of the pipe, which is convenient and efficient.

5. The rear chuck brakes quickly to ensure pipe cutting accuracy.

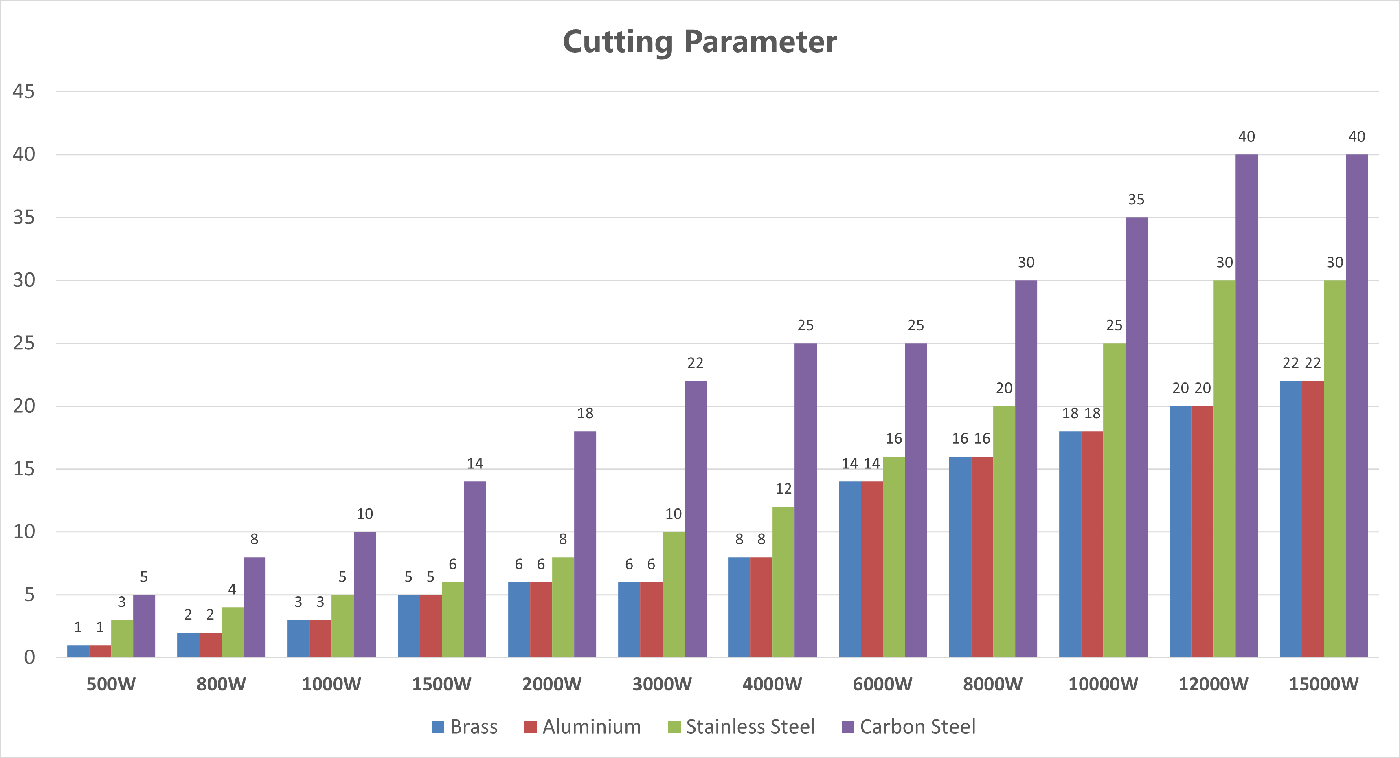

Different thickness need different laser power :

Main parts of fiber laser cutting machine :

Integrated Machine Bed:

•The unique industrial structure design gives it maximum stability and higher vibration resistance and damping quality.

•The compact spacing of 650mm ensures the agility of the chuck and the stability during high-speed driving.

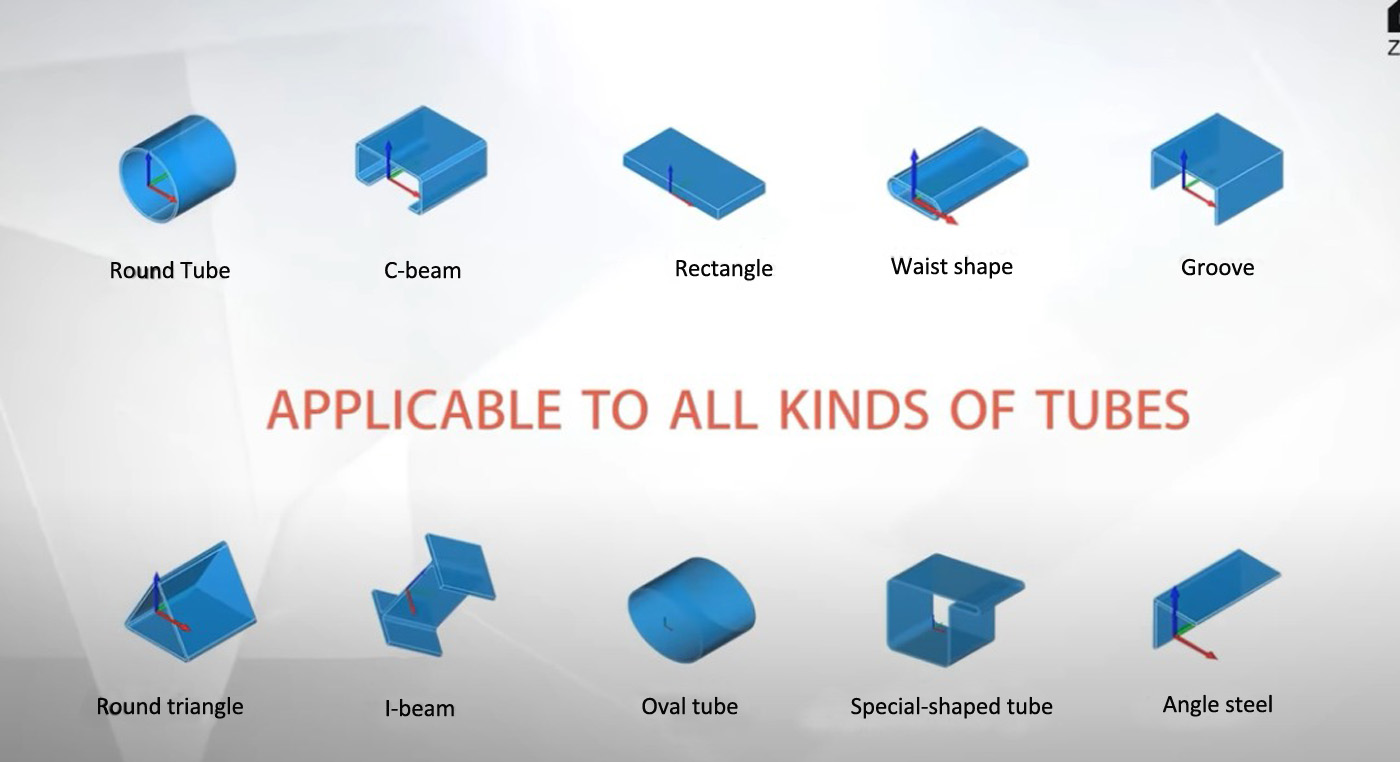

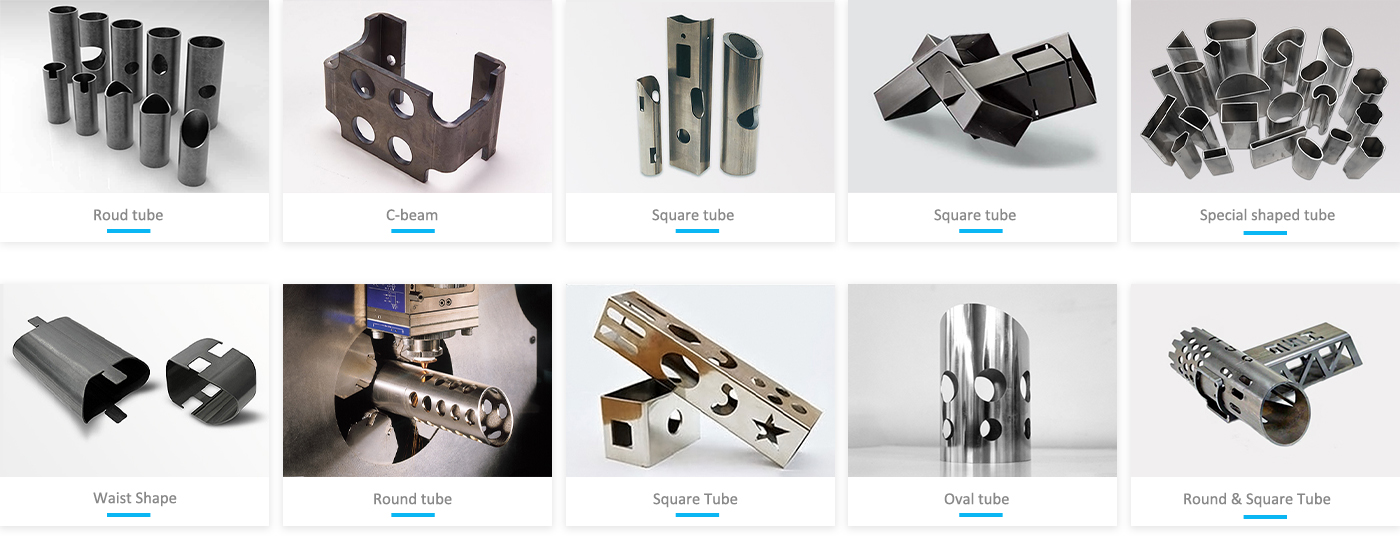

Cut Multi Types of Tubes

Not only cut conventional tubes like round, square and rectangular tubes, and profiles like channel, angle and H-shaped steels, also cut special-shaped tubes easily like triangular, concave, Land C-shaped tubes, etc.

Intelligent Digital Chucks

It is unnecessary to change claws while clamping 20-200mm tubes. Minimize tailing length.

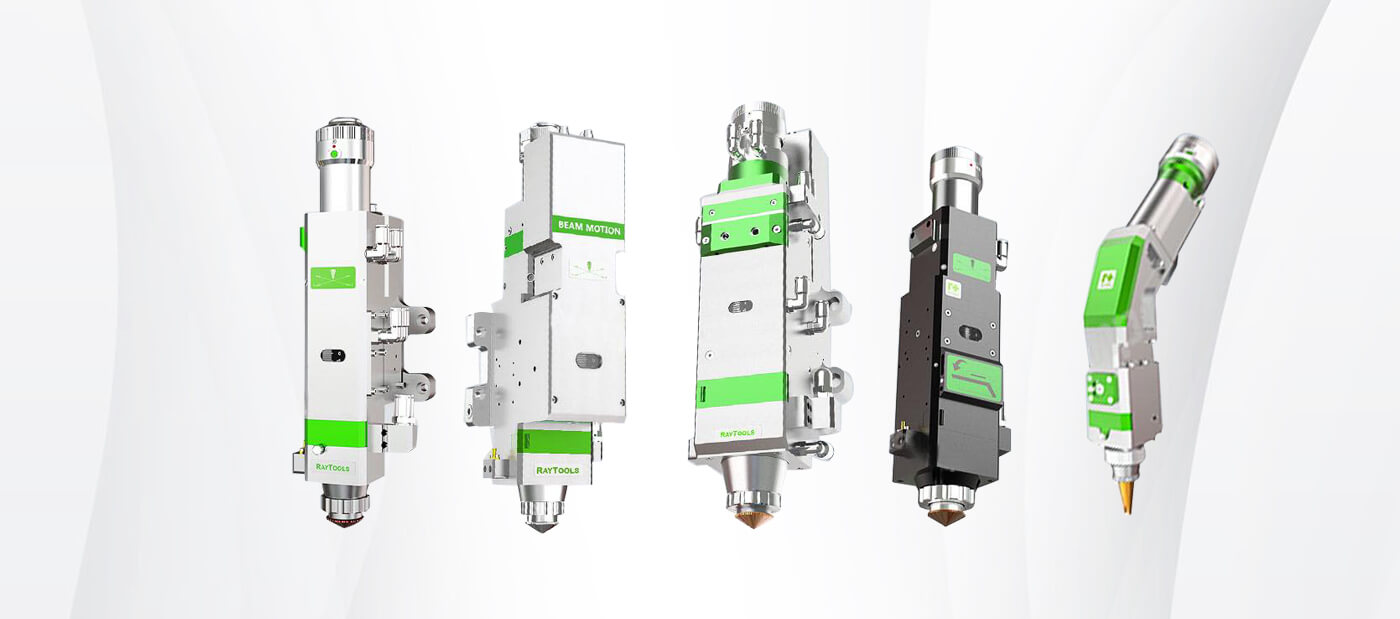

Auto Focus Cutting Head

• Laser head with automatic focus function, which can adjust the focus automatically, no need to adjust it by hand. The software can change the focusing lenses automatically according to the different thickness of the materials. It can shorten the perforation time, improve the perforation quality and cutting speed. It’s simple, convenient and fast.

• Long life span

Full-circle water cooling around the focusing component, which can realize no heat, no fog with high power cutting, small volume cutting and long term cutting, the lifetime of the cutting head is improved greatly.

Full Automatic Double Pneumatic Chuck

• The pneumatic chucks are 3 times faster than electric chucks due to one-key clamping and auto centering.

• With large and constant clamping force, heavy tubes will be clamped stably.

• Two rows of rollers are adopted for a wide range of clamping and high cutting precision.

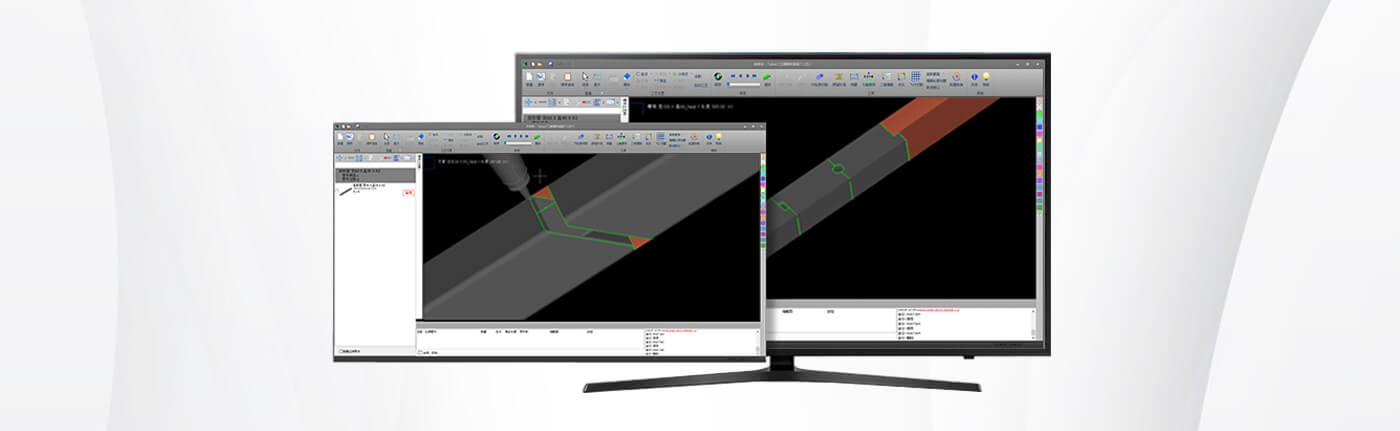

3D tube nesting software TubesT

TubesT is a 3D tube nesting software . From parts drawing and modification, full type compensation, strategic nesting to report generation, using TubesT will meet and exceed your production needs.

Parameters

| Model | ZL230G6-2 | ZL360G6-2 | |||||

| Laser Output Power | 6000w / 3000w / 2000w /1500w / 1000w | ||||||

| Chuck Quantity | 4 | 4 | |||||

| Shortest Remaining Material | 0 | 0 | |||||

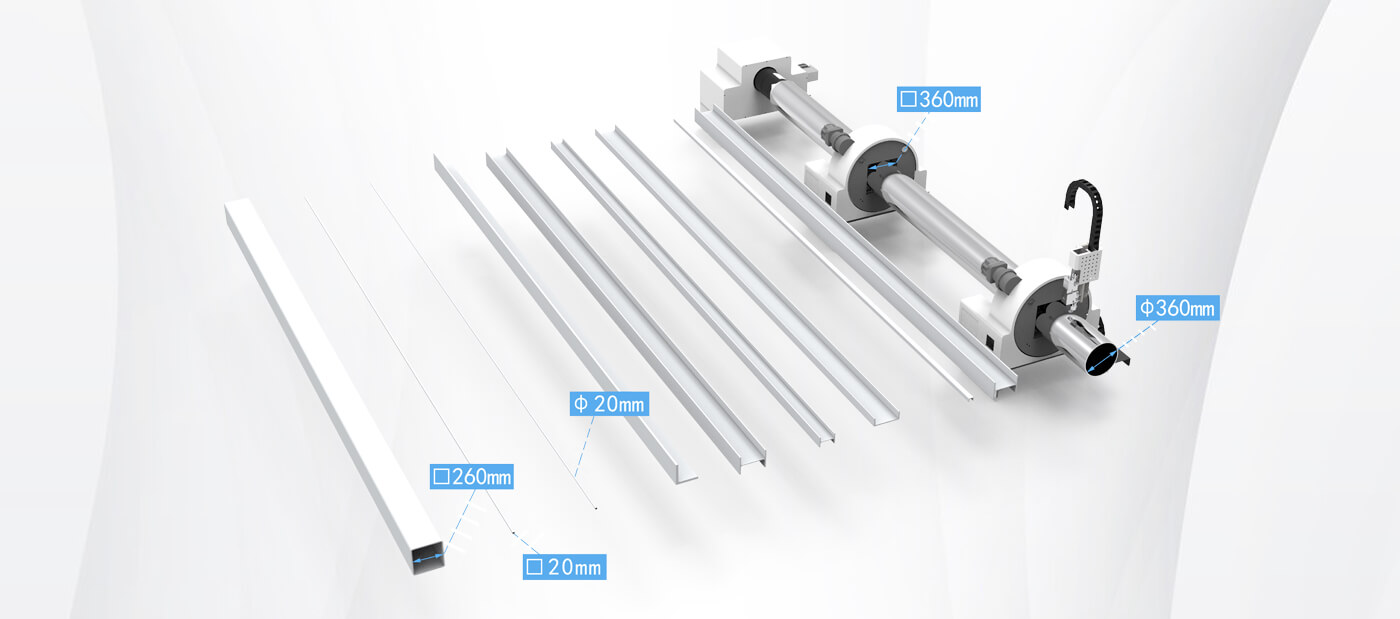

| Effective Square Tube Cutting Scope | □20*20-□160*160mm | □20*20-□360*360mm | |||||

| Rectangular Tube | Edge Length | 20mm-170mm | 20mm-300mm | ||||

| Outer Circle Diameter | ≤230mm | ≤360mm | |||||

| Effective Round Tube Cutting Diameter | Φ20-Φ170mm | Φ20-Φ360mm | |||||

| Max. Machinable Tube Length | 6500mm | 9200mm | |||||

| Max. Chuck Rotating Speed | 110r/min | 75r/min | |||||

| X/Y-Axis Positioning Accuracy | 0.06mm | ||||||

| X/Y-Axis Repositioning Accuracy | 0.04mm | ||||||

| Max. Tube Weight | 300kg | 800kg | |||||