Cutti ng Quality

ng Quality

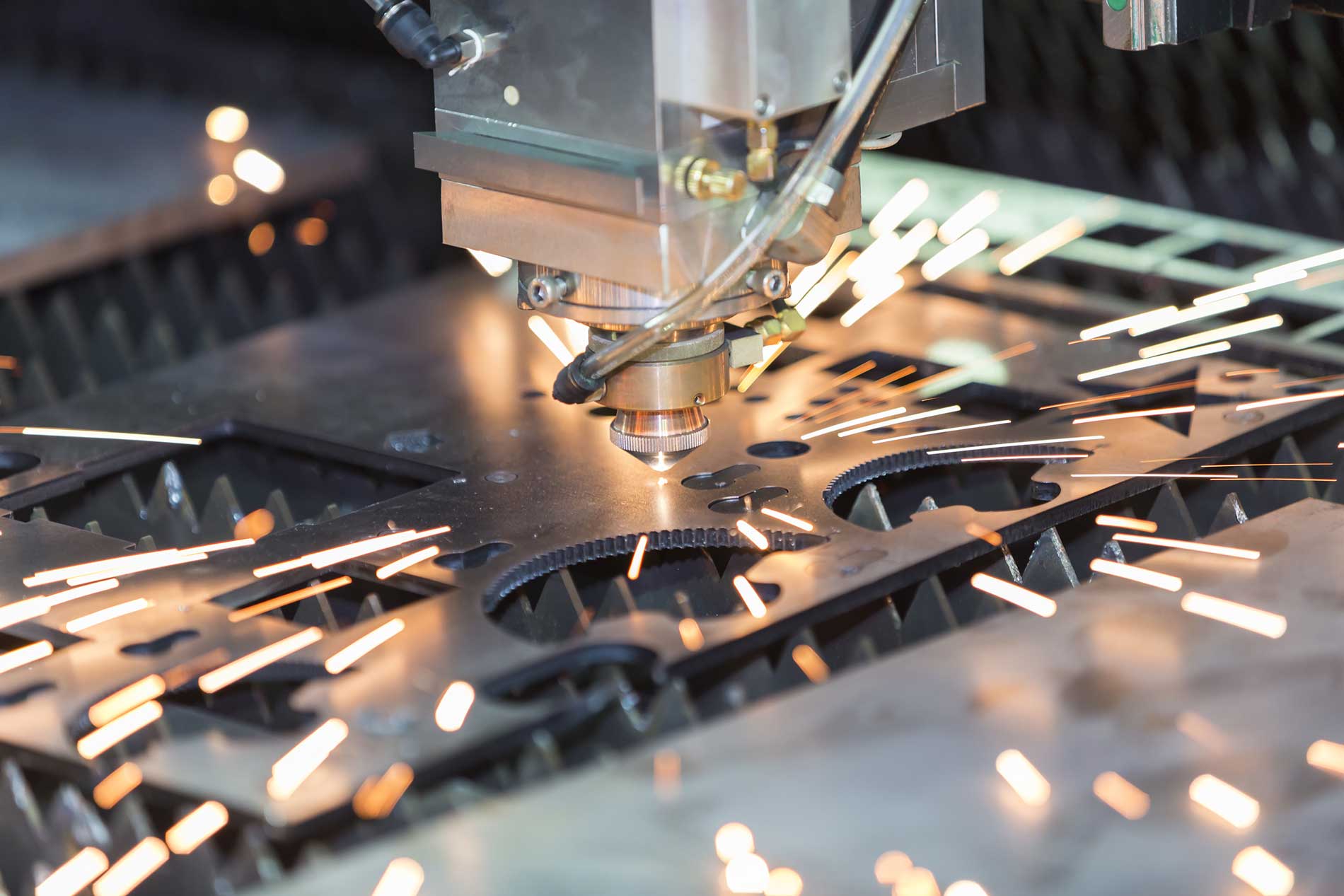

Cutting accuracy is the first element to judge the quality of CNC laser cutting machine. The four major factors affecting the cutting accuracy of CNC laser cutting machine:

1, the size of the laser cohesion of the laser generator. After gathering if the spot is very small, the cutting accuracy is very high, if the gap after cutting is also very small. This means that the laser cutting machine precision is very high, the quality is very high. However, the beam emitted by the laser is tapered, so the gap cut out is also tapered. Under these conditions, the greater the thickness of the workpiece, the lower the precision will be, so the larger the slit.

2, the precision of the worktable. If the precision of the worktable is very high, the precision of the cutting is also improved. Therefore, the accuracy of the worktable is also a very important factor in measuring the accuracy of the laser generator.

3, laser beam cohesion into a cone. Cutting, the laser beam is tapered down, then if the thickness of the cut workpiece is very large, the cutting accuracy will be reduced, then cut out the gap will be very large.

4, cutting different materials will also affect the accuracy of the laser cutting machine. In the same case, cutting stainless steel and aluminum cutting accuracy will be very different, stainless steel cutting accuracy will be higher, and the cutting surface will be smooth.

Generally speaking, the laser cutting quality can be measured by the following six standards.

1. Cutting surface roughness Rz

2. Cutting slag hanging size

3. Cutting edge perpendicularity and slope u

4. Cutting edge rounding size r

5. Streak back drag n

6. Flatness F