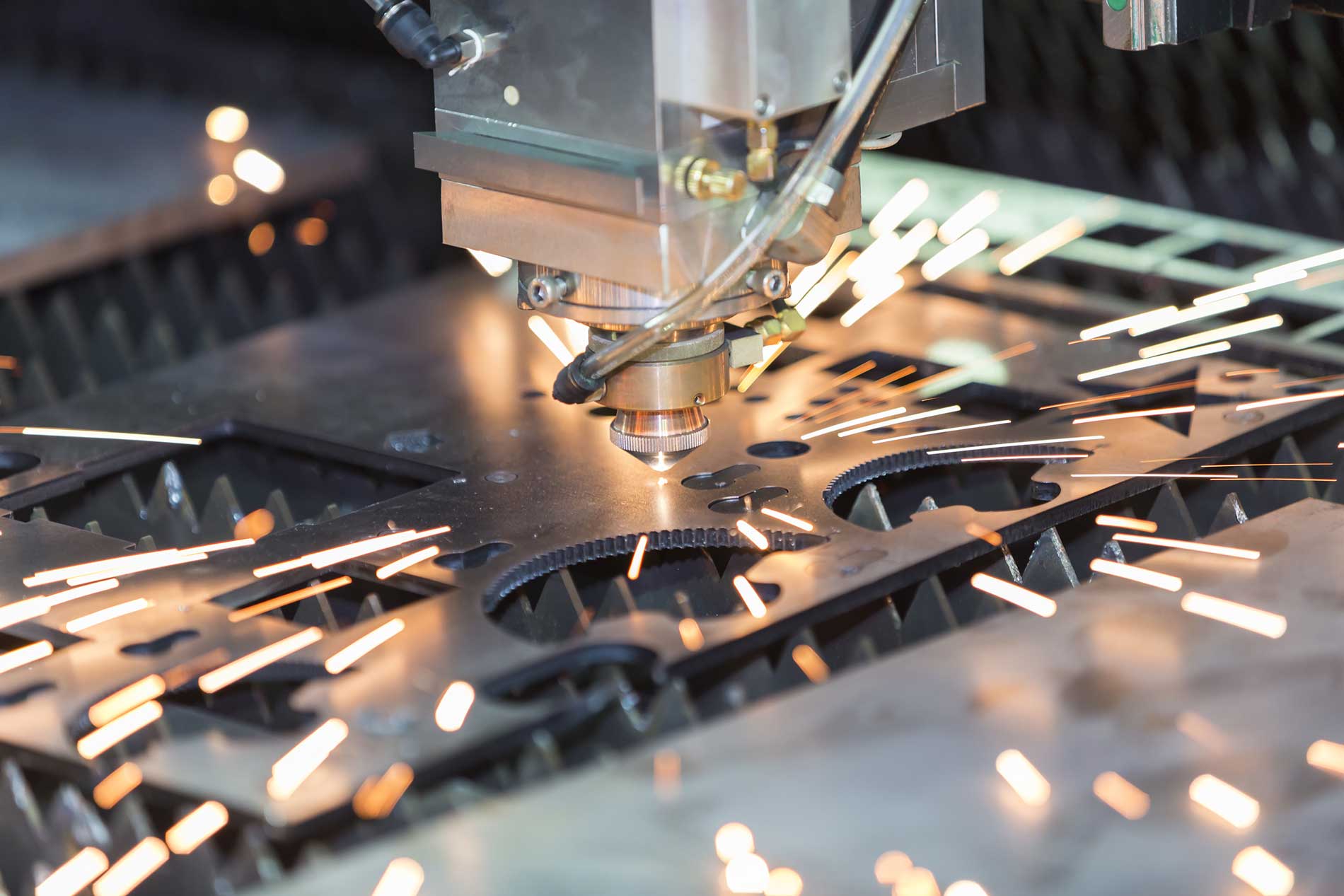

Choosing a laser cutting machine is not simply about comparing power and price. It is a comprehensive consideration of the four dimensions of materials, power, performance parameters, and services. Skip sales jargon, grasp the core essence, and in five minutes, let us help you clarify your thoughts and find the production tool tailored for your business. ”

1、 Clarify one’s own needs (the first step in selection)

절단 재료:

Carbon steel/stainless steel: Fiber laser is the preferred option with the highest cost-effectiveness.

Aluminum alloy/brass: requires higher power (due to high reflectivity) and is equipped with “anti high reflectivity” function.

Copper: the most difficult and requires a specialized model

2、 Material thickness and speed:

≤ 8mm (medium thin plate): 3kW-6kW power is the mainstream and the speed is the fastest.

8-20mm (medium thick plate): 6kW-12kW power, balanced speed and mass.

≥ 20mm (thick plate): 12kW-30kW+high power, ensuring cutting section quality and speed.

3、 Key performance parameter verification

Positioning accuracy/repeatability accuracy: at least ± 0.03mm/m and ± 0.02mm.

Maximum acceleration: ≥ 1.5G (high acceleration means high cutting efficiency for corners and small shapes).

Ultimate cutting speed: ≥ 60m/min (idle speed affects typesetting efficiency).

4、 Manufacturer Services

How long is the after-sales service time for the whole machine? What is the warranty period for the laser?

What are the contents of the training?

What is the response time for after-sales engineers?

The ‘best’ may not necessarily be the ‘most suitable’. Equipment that meets your current needs with appropriate margin and reliable after-sales service is your best choice. Do not simply pursue low prices or ultra-high configurations while neglecting long-term stability and total cost of ownership