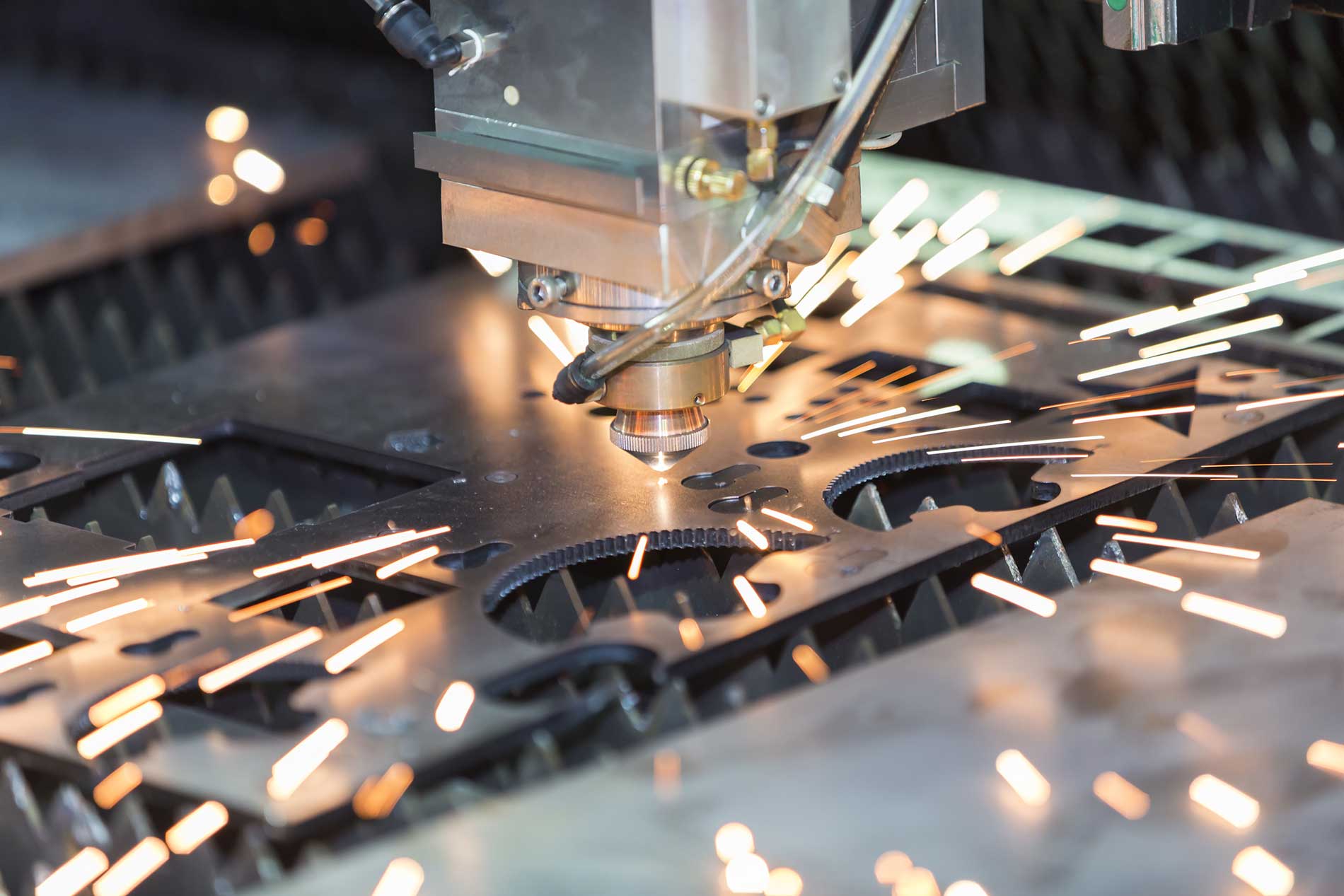

Laser cutting technology utilizes the high energy density generated by focusing high-energy laser beams to rapidly heat materials below their vaporization temperature and melting point, causing them to vaporize or melt rapidly.

So, what are the advantages of laser cutting for flange processing?

1. Good effect: Laser cutting can precisely control the cutting thickness and size, resulting in high-precision cutting effects.

2. Less burrs: Compared with other cutting methods, laser cutting produces very few burrs, which makes the surface of the workpiece smoother and smoother.

3. Cost reduction: Due to the precise control of cutting thickness and size by laser cutting, it can reduce raw material waste, lower production costs, and be reasonably priced.

4. Easy to process: Laser cutting materials have relatively low hardness, making them easy to process and also suitable for a variety of different materials.

5. Strong adaptability: Laser cutting can cut various irregular parts, such as circular, square and other shaped components. Laser cutting can adapt to different processing needs, and can achieve good processing results for both simple and complex mechanical parts.