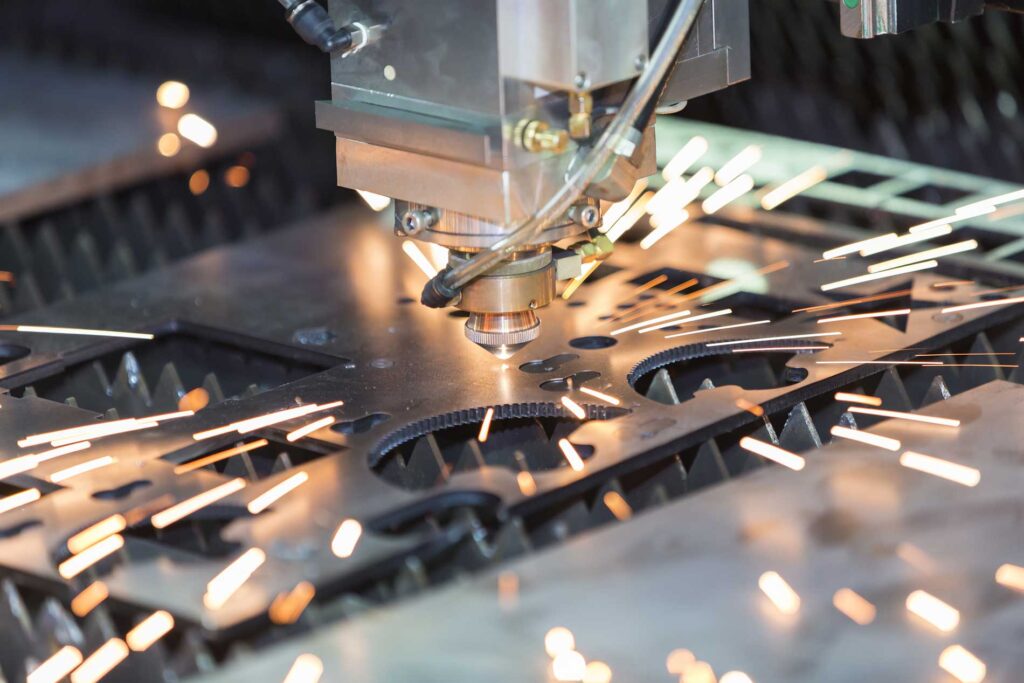

Laser cutting machines are designed for different metal materials, such as stainless steel, carbon steel, alloy steel, aluminum plate, titanium, iron, etc. The cutting thickness of different power laser cutting machines is closely related to the cutting material.

The power of high-power metal laser cutting machine can be divided into 1000W-25000W, so how many watts of laser cutting machine should be used to process 25mm thick carbon steel plate?

The ability of laser cutting machines to cut metal is closely related to factors such as cutting quality, auxiliary gas used, cutting speed, etc. At the same time, laser cutting machines with different powers have different cutting thickness limits for different metal materials.

1000W fiber laser cutting machine can cut different materials with a maximum thickness of 10mm for carbon steel; The maximum thickness of stainless steel is 5mm; The maximum thickness of aluminum plate is 3mm; The maximum thickness of copper plate is 3mm;

3000W fiber laser cutting machine can cut different materials with a maximum thickness of 20mm for carbon steel; The maximum thickness of stainless steel is 10mm; The maximum thickness of aluminum plate is 8mm; The maximum thickness of copper plate is 8mm;

6000W fiber laser cutting machine can cut different materials with a maximum thickness of 25mm for carbon steel; The maximum thickness of stainless steel is 15mm; The maximum thickness of aluminum plate is 12mm; The maximum thickness of copper plate is 12mm;

It can be seen that the 25mm thick carbon steel plate can be cut with a 6000W laser cutting machine. The cutting ability of a laser cutting machine is also related to various factors such as cutting quality, laser type, cutting environment, cutting speed, etc. The use of auxiliary gas can also improve certain cutting ability and cutting quality. Therefore, there is no absolute standard to judge its cutting thickness, and specific adjustments should be based on actual operation.