The dust collector plays an important role in the fiber laser cutting machine

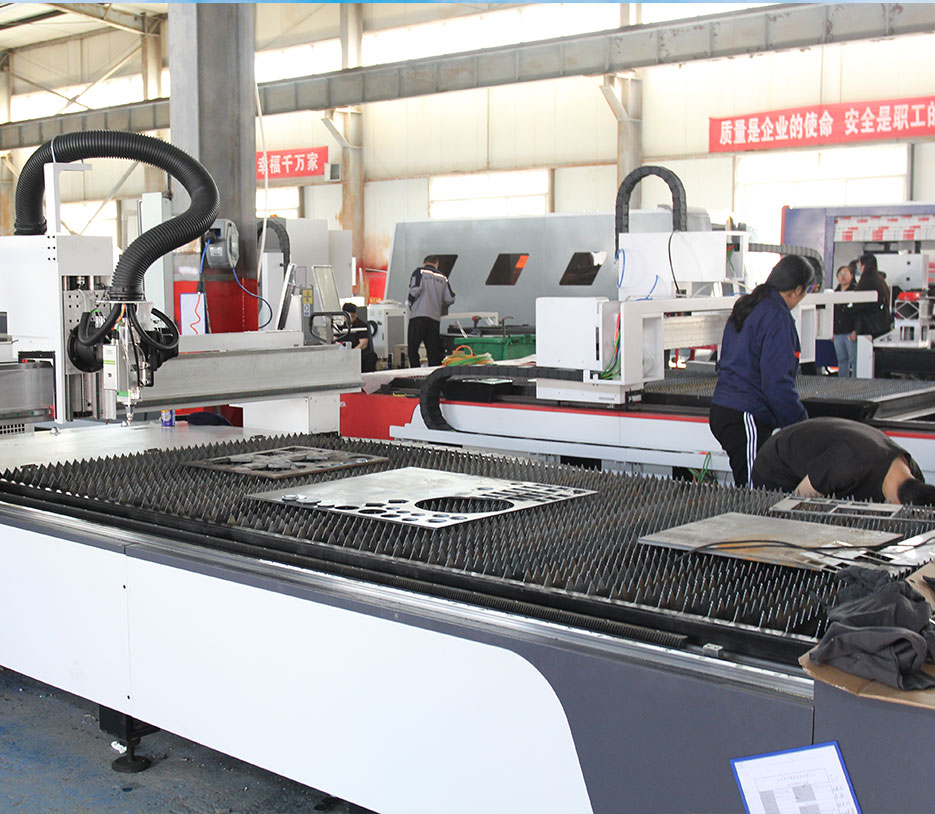

With the emergence of fiber laser technology, fiber laser cutting machines have occupied an important position in the field of sheet metal processing. Fiber laser cutting machine in the process of processing the workpiece, high temperature ablation will produce a lot of smoke and dust, which will pollute some precision parts on the equipment. At the same time, smoke can also have adverse effects on the health of operators. If the dust generated by cutting is not treated, it will affect the service life and cutting performance of the fiber laser cutting machine, so the dust removal system of the fiber laser cutting machine is particularly important.

The dust collector is mainly used to collect the dust generated by the fiber laser cutting machine in the cutting process, and then purify it. Generally, the dust removal system of the laser cutting machine is designed as a whole ventilation structure with a large cavity. In order to meet the requirements of environmental protection, it is necessary to use high-power dust collector, which covers a large area, and the installation of pipelines is complicated, which is easy to cause air leakage. Resulting in poor ventilation. In actual work, the smoke produced by the cutting machine can not be discharged in time, which will affect the working environment of the user.

One solution is to divide the lower part of the laser cutting machine table into several chambers of equal geometry arranged longitudinally with a partition board, and have a main suction pipe in front. The main suction pipe is connected with the dust collector; There is a valve between each chamber and the main suction duct, and the mechanical control valve controls the cylinder through the inlet duct and the outlet duct; There is a hopper in the small room, which is sealed by a welded end plate at both ends, and a number of air holes are arranged at the lower part of both sides of the hopper. The ventilation process of the system is controlled through the opening and closing of the valve. This method saves space and improves dust removal effect.

Another solution consists of a main body, a main box, and a control cabinet. A dust cover is provided to absorb all the dust produced by the fiber laser cutting machine during operation. This can ensure a clear line of sight and improve work efficiency. Dust cover can also be used when working. It ensures that the residue will not splash around, protects the safety of the operator, adds a layer of protection, and improves the popularity and applicability of the equipment.

Although the dust removal system is not the most important consideration when choosing a fiber laser cutting machine, an efficient dust removal system is an important condition to ensure normal production and must not be ignored.

How it works:

1. After the fiber laser cutting machine is started, the supporting dust collector begins to work.

2. The dust generated by fiber laser cutting passes through the reserved tube port of the laser machine and enters the purifier under the power of the purifier exhaust gas.

3. After entering the purifier, the spark smoke first enters the spark trap. When the spark dies down, it falls into the ash hopper.

4. Then the fine dust enters the surface of the filter element. Coarse particles collide with each other under the action of wind force and inertia force, and naturally settle to the bottom ash hopper. Fine-grained, low-density dust particles are processed through a process that combines diffusion and filtration. The effect is deposited on the outer surface of the filter material of the filter cartridge and intercepted.

5. The filtered clean gas penetrates the filter material and is discharged from the inner wall of the filter cartridge.

6. The trapped smoke pollutants in the filtration process will cover the surface of the filter material and gradually accumulate. The automatic pulse recoil cleaning system starts, the compressed air automatically blows the cleaning filter element, and shakes the dust to the dust collecting drawer.

The fiber laser cutting machine will not produce a lot of smoke and dust when working as the traditional plasma cutting method. Fiber laser cutting machine has a special dust removal device, the collected dust is directly transported to the dust filtration and purification equipment, after uniform filtration and purification, until the standard. The smoke produced by cutting is basically formed under the cutting of the workpiece. Therefore, in order to save equipment investment and improve ventilation efficiency, only the area in the cutting process is vacuumed. The side of the fiber laser cutting machine has an air outlet. This kind of structure is relatively simple, the dust removal effect is good