With the continuous progress of science and technology, kitchenware is now more and more exquisite, but I do not know if you have ever thought about the question of how it is produced? In the kitchenware processing industry, such as hoods, burners, stove panels, large commercial kitchen products such as sheet metal panels are used in large quantities. Produced with the traditional process requires a large number of molds, design. But the manufacturing cycle is long, the cost is high. That fiber laser cutting machine can be used in the kitchenware industry? Today I will say a few words on everyone.

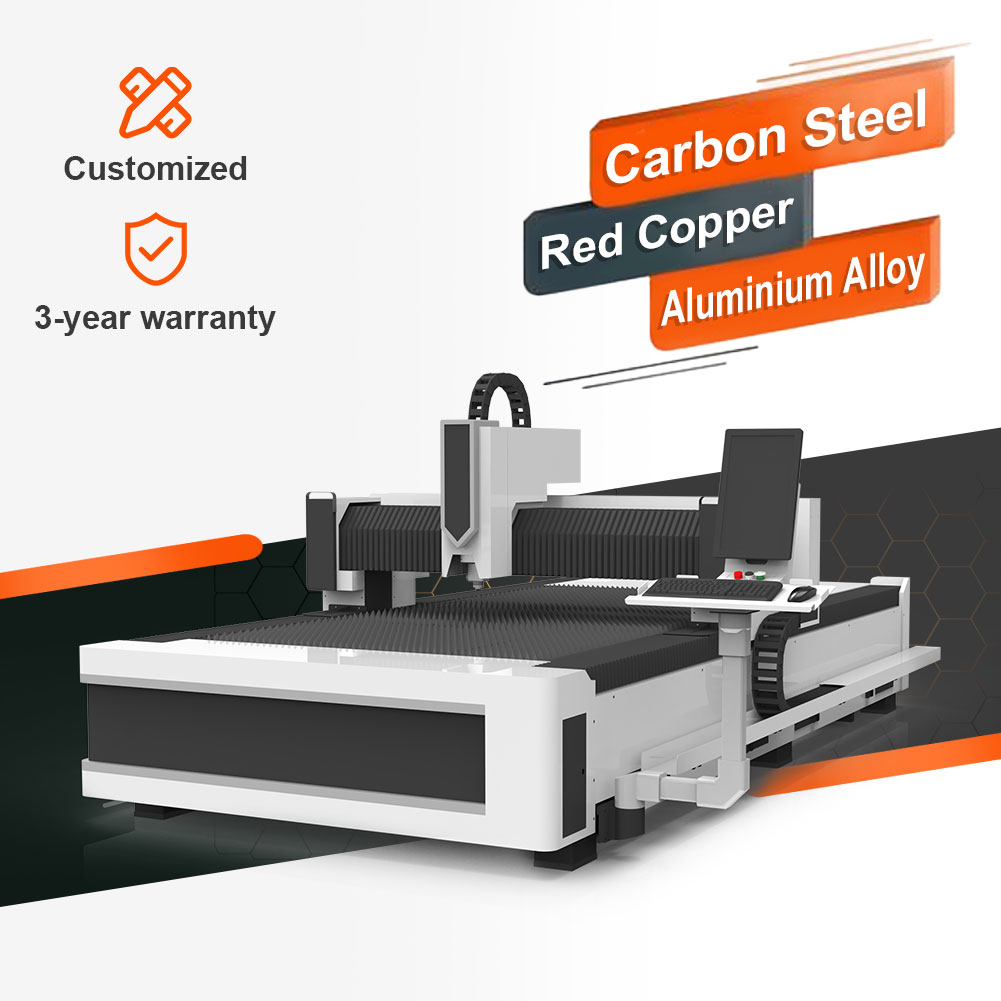

In the kitchenware manufacturing process, fiber laser cutting machine can quickly cut a variety of materials, such as stainless steel, aluminum alloy, ceramics and so on. Compared with the traditional cutting method, the cut material has a smooth surface and high precision, which can meet the high requirements of kitchenware manufacturing. And nowadays, people have higher and higher requirements for daily living goods and utensils. Both require chic appearance, but also require versatile and durable functions. Cutting machine can still meet these requirements.

And the fiber laser cutting machine is very widely used. It can be used to manufacture various types of kitchenware, like stainless steel sinks, range hoods, stoves and so on. Manufacture more beautiful and practical kitchenware products. At the same time, fiber laser cutting machine can also be used to produce a variety of metal products, such as metal sheet, metal pipes and so on. So the laser cutting machine has unique advantages in the kitchenware industry, and these advantages make the laser cutting machine an ideal choice in the kitchenware processing industry.